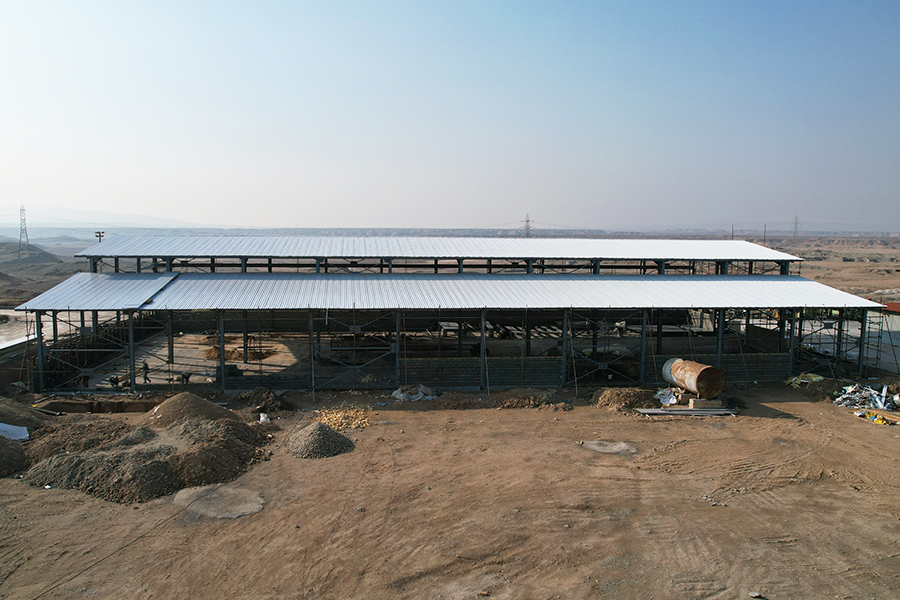

This project, located alongside the Tehran-Qom highway, is recognized as one of the most advanced and technically engineered industrial buildings in the region. The project is built on a 2,000 square-meter plot of land and features 1,850 square meters of covered space spread over one floors.

During the initial planning stages, the design was adjusted several times to align with the site’s specific geotechnical and operational requirements. As the engineering team conducted in-depth assessments of the site conditions and production needs, the final design settled on 1,850 square meters of built-up area, optimized for both functionality and structural performance. These adaptations led to major changes in the architectural and structural layout, becoming one of the defining challenges of the project.

Projects always come with challenges, from technical issues to time and budget constraints. But we, as engineers, use our knowledge and creativity to find innovative solutions and overcome any challenge.

To address the challenges of the soil, advanced soil stabilization techniques were used:

One of the standout features of this project is its unmatched precision in execution. For example:

In this project, the execution of heavy-duty foundations for industrial equipment embedded in the flooring was another key feature. These foundations were specifically designed and installed to ensure smooth long-term operation and production without issues.