Located along the Tehran–Qom highway in Shamsabad Industrial City, the Sazeh Pardazan project stands out as one of the region’s most technically refined and modern industrial facilities. Built on a 3,000 square meter plot, the facility comprises 3,000 square meters of usable space across three floors.

During the early planning stages, the project design underwent several revisions to align with the site’s geotechnical conditions and operational requirements. After comprehensive engineering assessments and design optimization, the final built-up area was set at 3,300 square meters. This adjustment required major changes in the architectural and structural plans, marking one of the project’s primary technical challenges.

Projects always come with challenges, from technical issues to time and budget constraints. But we, as engineers, use our knowledge and creativity to find innovative solutions and overcome any challenge.

The primary electrical conduits were embedded directly into the facility’s concrete flooring. This approach ensures enhanced safety, clean aesthetics, and easy future maintenance. The execution required careful coordination during concrete pouring and leveling to preserve alignment and accessibility.

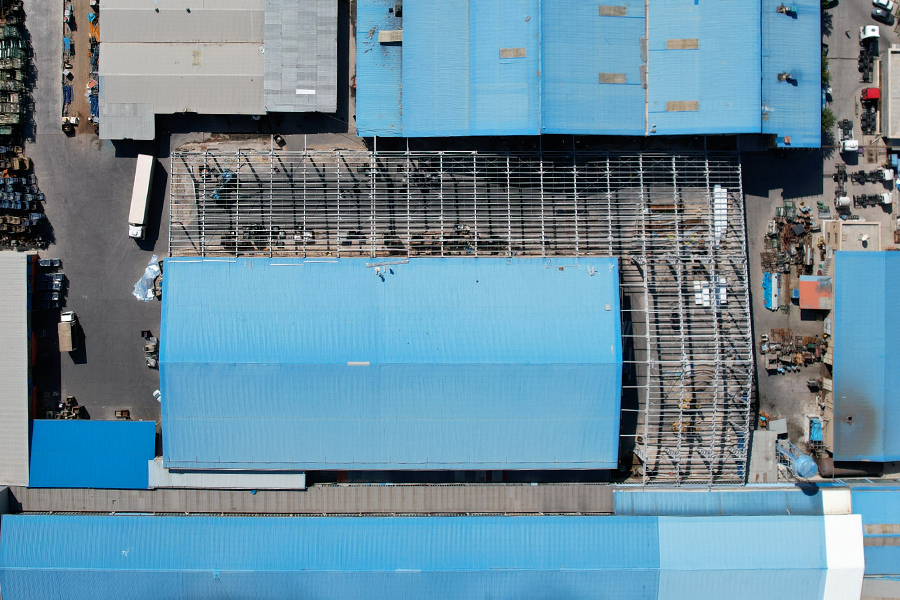

A major highlight of the project lies in the meticulous execution of its steel structural system. All steel columns and load-bearing elements were installed with high precision, adhering to strict industrial standards. Welding, alignment, and connections were executed with accuracy, ensuring long-term stability and structural reliability.

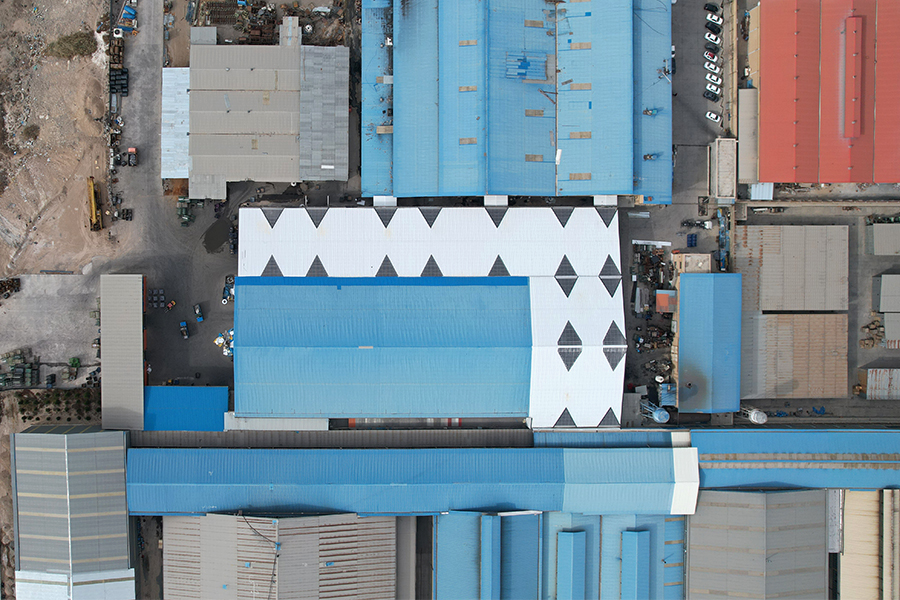

One of the most unique architectural features of the facility is the implementation of triangular skylights on the roof. These skylights not only provide ample natural daylight to the workshop floor but also give the structure a distinctive visual identity. Their geometric complexity required custom detailing and accurate installation, contributing to both energy savings and an enhanced working environment.

The workshop floor was constructed using high-strength reinforced concrete, capable of withstanding heavy machinery loads. The concrete mix was chosen to resist abrasion, mechanical impact, and industrial wear, meeting the rigorous standards of a high-performance production environment.